Driving sustainability: Cutting energy consumption in cold storage

Reducing the ecological footprint in production by analyzing energy consumption and striving for efficiency improvements.

- Identification of all energy consumers

- Detailed insight into energy consumption

- Making evidence-based decisions to take actions

Together, we’ll evaluate your requirements and discuss how to implement energy management digitization using our analysis tools.

Energy efficiency in focus: Sustainable measures of a globally operating snack manufacturer

Creating a sustainable and efficient storage solution

A leader in the snack manufacturing industry is taking action to reduce its energy consumption and promote sustainable practices. With a global presence spanning many decades and operations in more than 30 countries, this company is committed to environmentally friendly measures.

Setting measurable goals

The company’s ambitious goal is to significantly reduce CO2 emissions, decrease water consumption and minimize non-edible waste by 2025. The showcased project contributes to these commendable objectives.

Installing eco-friendly cold storages

In pursuit of minimizing environmental impact and optimizing energy usage, the company is committed to enhancing energy efficiency across its entire value chain. A recent project conducted at a production plant in Romania exemplifies this commitment.

The primary goal of this initiative is to establish a foundation for further optimization by conducting a comprehensive analysis and measurement of energy consumption during cooling processes. Precise energy measurements allow for the identification of potential efficiency gains, enabling targeted measures to be implemented. The project’s focus lies in reducing resource consumption, ultimately contributing to a smaller ecological footprint in production.

The identification of potential efficiency gains is enabled by precise energy measurements and analytics during cooling processes.

Technical hardware setup

Energy consumption monitoring

The EMpro energy meters facilitate comprehensive monitoring of energy consumption in the company’s large cooling chambers. This is especially crucial because refrigeration equipment tends to be one of the most significant energy consumers in production.

By closely tracking consumption patterns, the company identifies potential savings opportunities. Whether it’s adjusting cooling settings, optimizing maintenance schedules or upgrading equipment, the insights provided empower the company to reduce energy waste and enhance overall efficiency.

Non-invasive energy monitoring

From a technical standpoint, the EMpro energy meter operates using a Rogowski coil that encircles the appliance to be monitored. This coil generates a signal based on the current flowing through the appliance’s conductor. This non-contact method enables energy consumption detection without the need to open the appliance or disrupt its operation. Notably, this installation approach can be carried out during operation. In this project the method is used to monitor electrical energy and power.

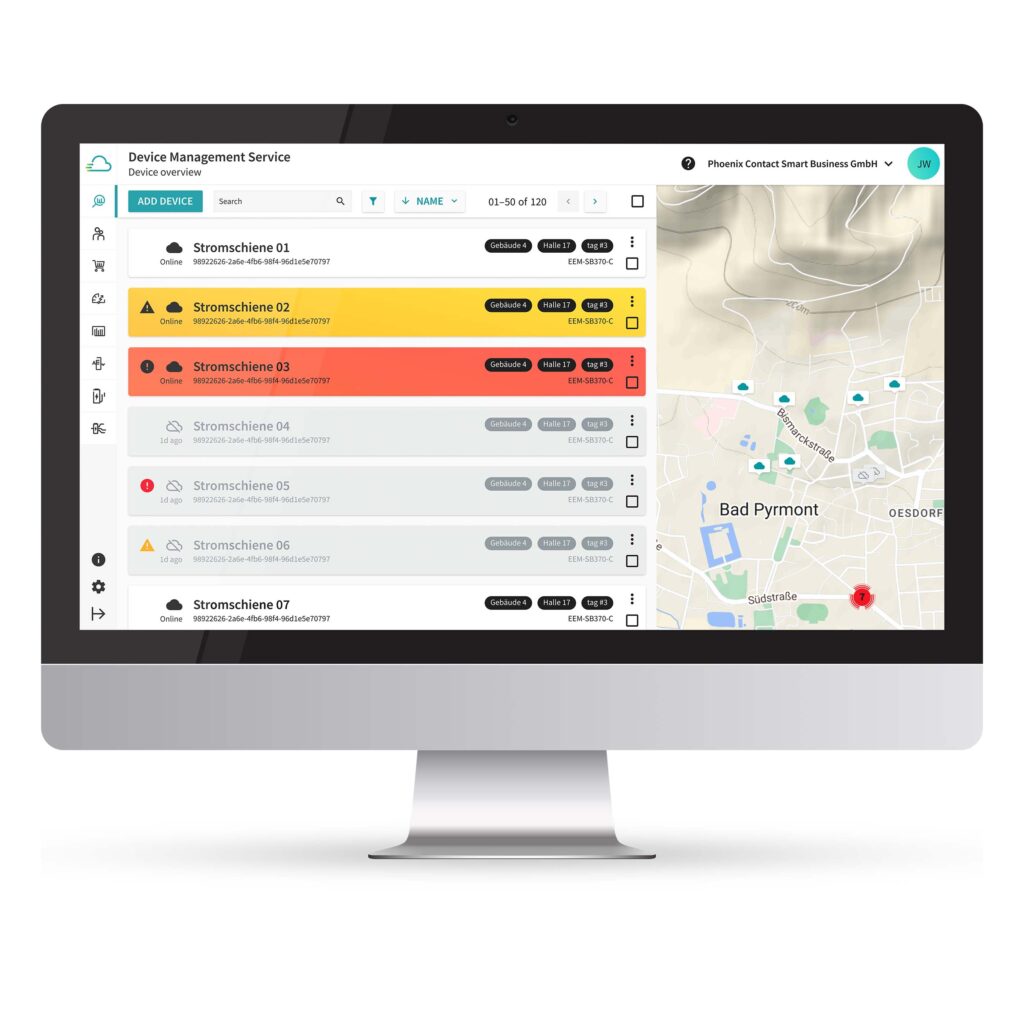

Seamless data integration

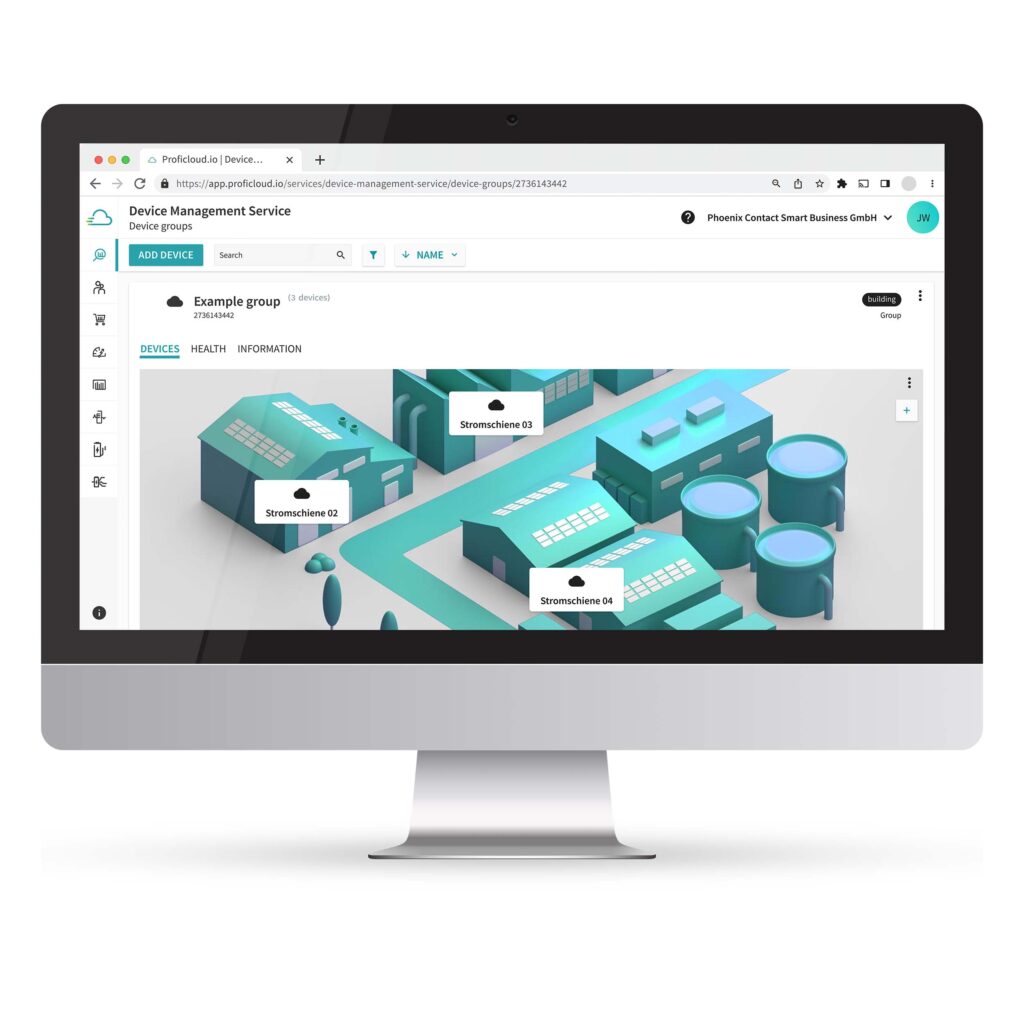

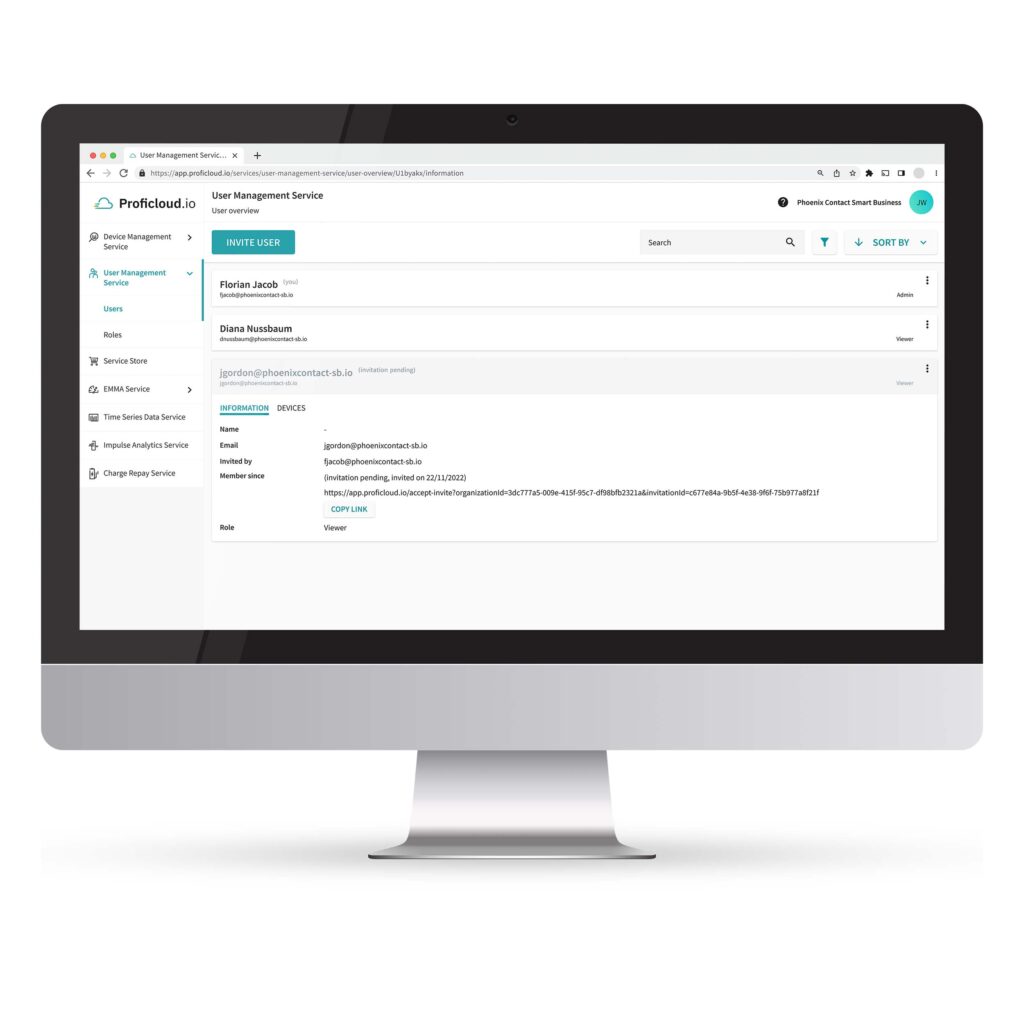

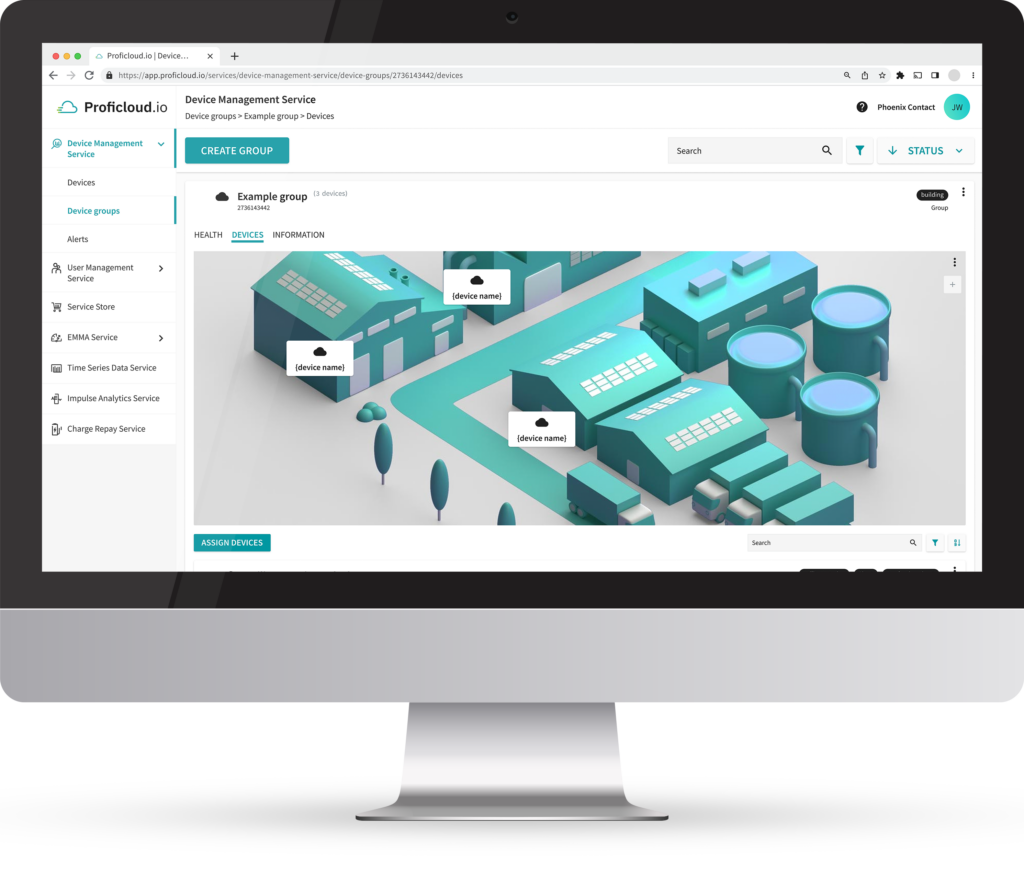

Another technical advantage is that the EMpro energy meters can transfer the collected energy data directly to Proficloud.io for management and analysis. Integration with Proficloud.io enables efficient data collection and analysis without the need for additional control systems. Connecting the EMpro energy meter via internet to the Device Management Service by entering the UUID (Universal Unique Identifier) enables fast insight into the hardware device itself. This creates an efficient solution for monitoring and controlling the energy consumption of refrigeration appliances with the EMMA Service, enabling the company to proactively respond to extraordinary consumption and realize savings.

Maximize value with Smart Services

The Smart Services of Proficloud.io added the needed digitalization component of the project.

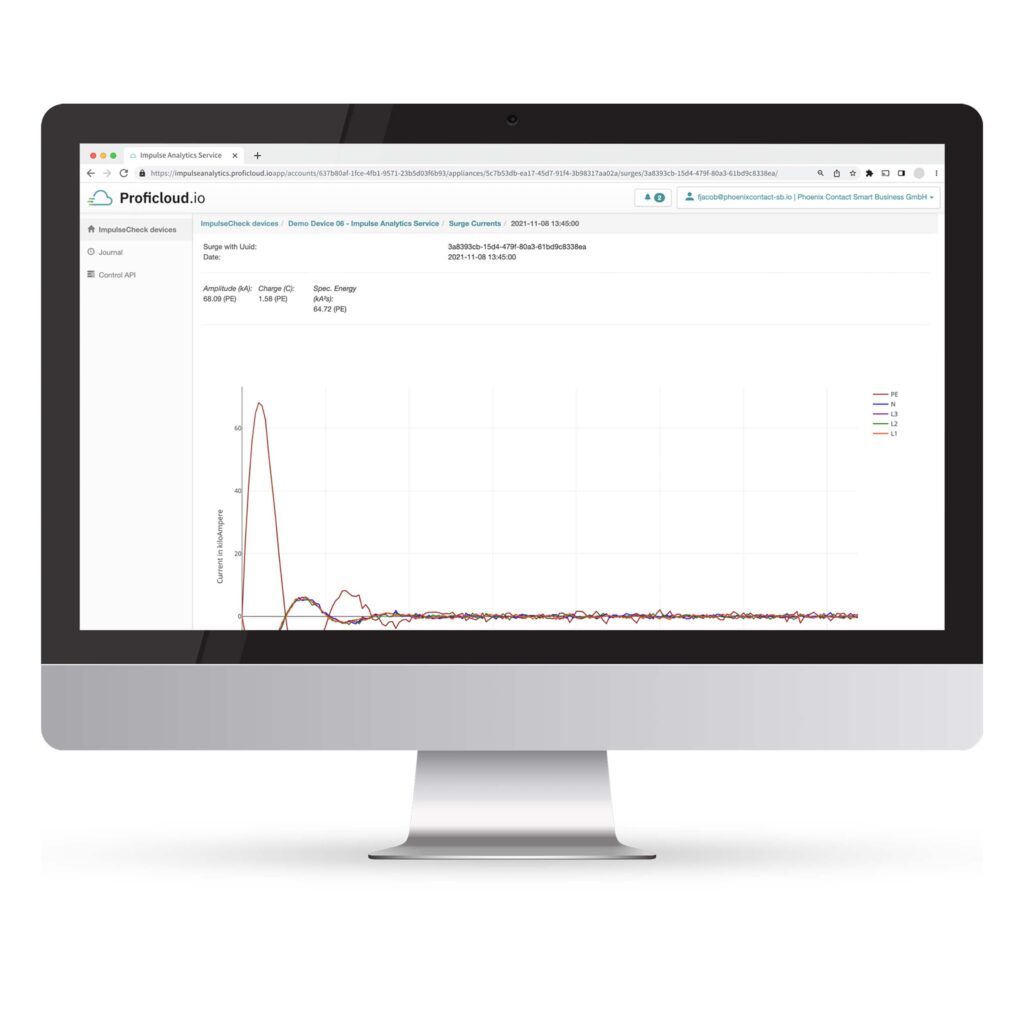

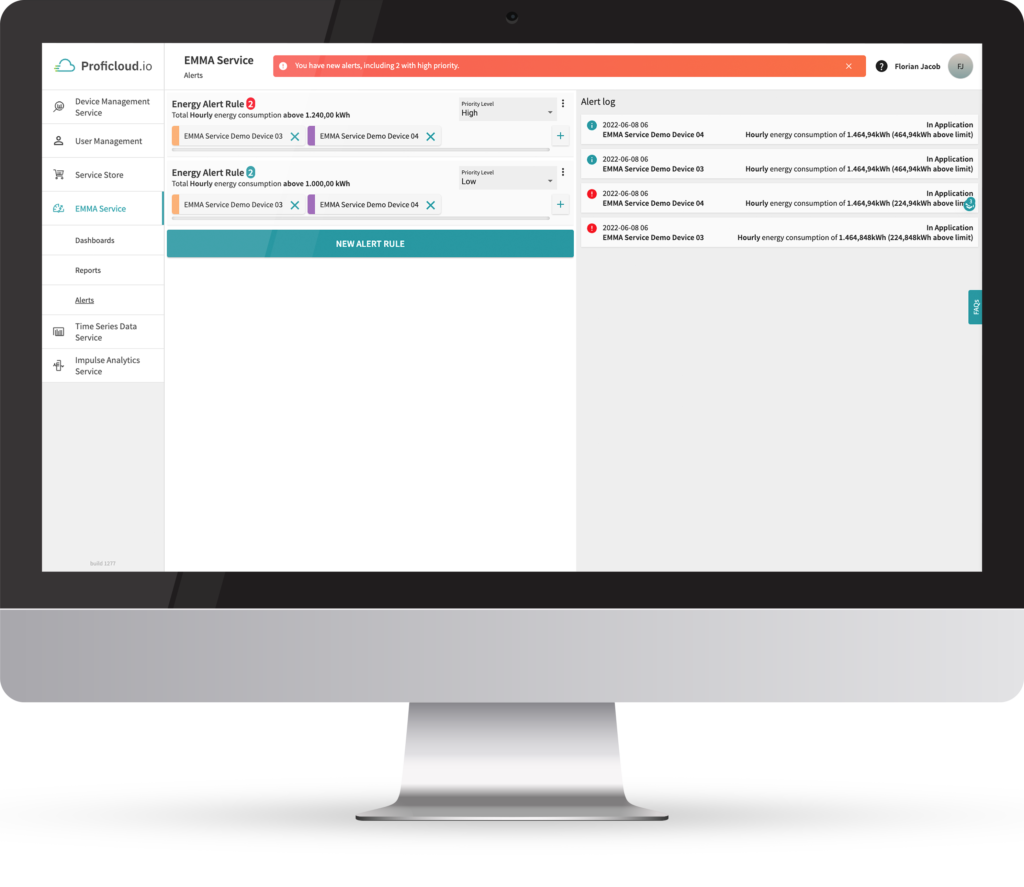

EMMA Service: Smart Energy Monitoring, Management, Analytics

The EMMA Service enables remote access to energy and power data using IoT-enabled measuring devices. It allows monitoring, analysis and evaluation of this data through user-friendly dashboards and diverse visualization options.

Energy management with the EMMA Service is crucial for several reasons:

- Cost reduction: EMMA Service helps organizations significantly reduce energy costs, leading to potential savings. It provides valuable benchmarking data for performance evaluation.

- Efficiency and sustainability: By monitoring, analyzing and evaluating energy data, the EMMA Service enables informed decision-making. Organizations can define and implement measures to lower energy consumption, increase efficiency and reduce their carbon footprint.

- Remote monitoring: The EMMA Service’s user-friendly dashboards allow for easy access to critical energy data. With remote monitoring, companies can streamline workflows, save time and make better decisions.

- Compliance and certification: Implementing the EMMA Service aligns organizations with ISO 50001 standards, which can lead to certification.

The EMMA Service empowers efficient energy management, cost savings and sustainability.

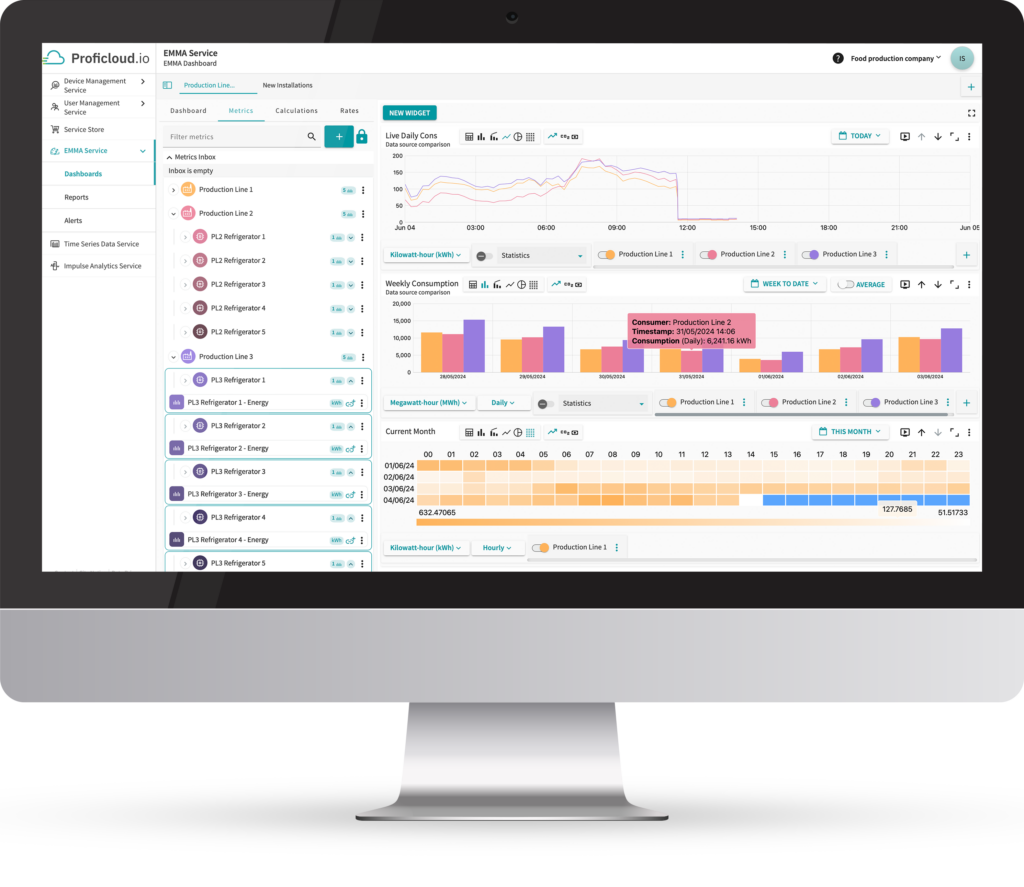

View into the dashboards of the project

Energy consumption metrics for production lines

The dashboard provides detailed energy consumption data for each of the three production lines, including real-time, short-term and long-term trends:

- Live Data (Today): The first widget provides real-time energy consumption data for today. It’s represented as a line chart, showing fluctuations throughout the day.

- Short-Term (Weekly): The second widget displays short-term energy consumption trends over the course of a week. This information is visualized using a bar chart.

- Long-Term (Monthly): The third widget presents long-term energy consumption patterns on a monthly basis. It uses a heat map to highlight variations over time.

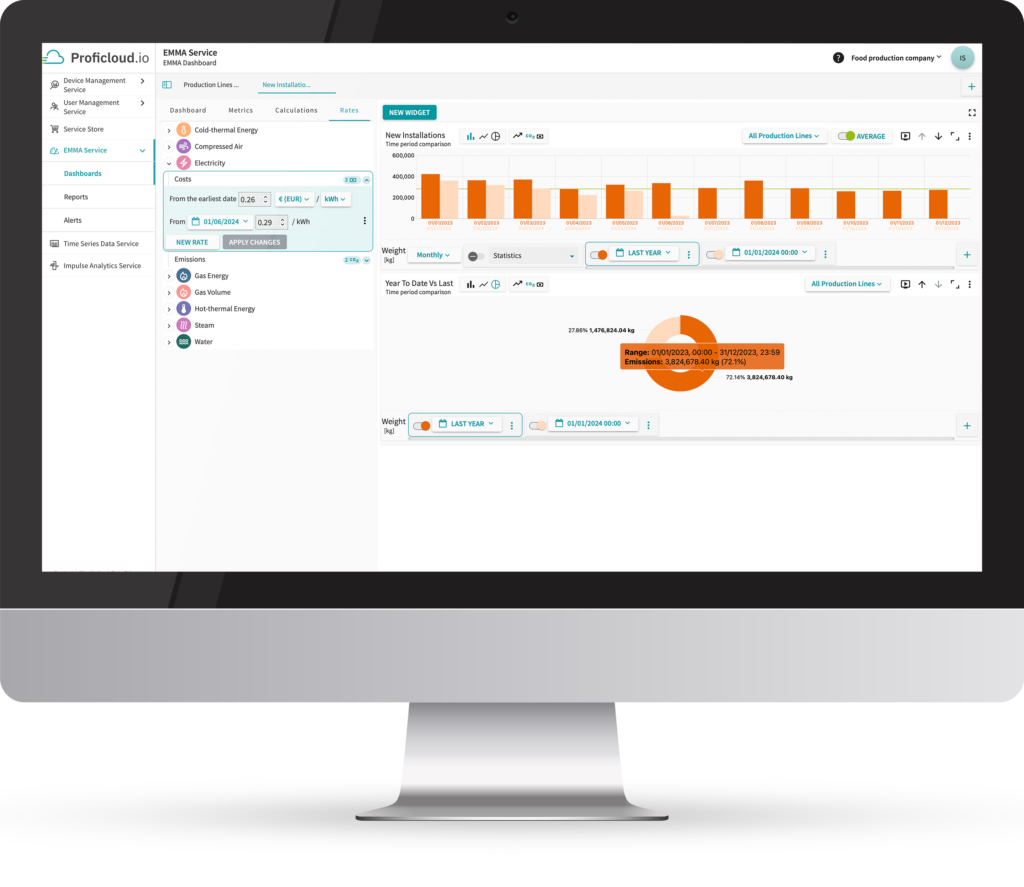

Comparing CO2e emissions: Old vs. new refrigeration installations

The EMMA Service dashboard provides detailed data on the CO2e emissions of both the old and new refrigeration installations and compares the data:

- Detailed Data: The dashboard provides in-depth information on the CO2e emissions for both the old and new refrigeration installations.

- Time Period Comparisons: The CO2e emissions between the old and new installations over different time periods are set in comparison, to assess the effectiveness of the new installation in reducing emissions.

Overcoming challenges

The project presented two challenges:

- Budget constraints: With limited financial resources, the company needed to strategically allocate funds to achieve its goal.

- IT resource limitations: The IT team and technical infrastructure faced resource constraints. The company sought a solution provider who could work within these existing limitations.

Further information

Hi, my name is Hendrik Schramm and I am glad to help you out!

Please do not hesitate to contact me. Also, if you have any suggestions or comments, just send us a message to inbox[at]phoenixcontact-sb.io and we will answer as soon as possible.