Energy management: Creating sustainability and reliability energy solutions

A monitoring solution for a photovoltaic system to ensure continuous production during an energy shortage.

- Detailed insight into energy consumption

- Innovative set up to track data for generated energy

- Monitoring and alerting of threshold values

- Handling electrical surges to safekeep facilities and machinery

Together, we’ll evaluate your requirements and discuss how to implement energy management digitization using our analysis tools.

Overcoming national energy shortages with natural ressources

Creating solutions from challenges: Photovoltaicenergy system and monitoring for the whole factory site

Phoenix Contact South Africa unveiled an innovative photovoltaic energy project addressing South Africa’s persistent load shedding. Load shedding, introduced in South Africa to prevent a total power outage, involves planned power cuts in rotating areas of the country.

The photovoltaic system, integrated with the Smart Service Time Series Data Service, ensures efficiency and adaptability. The project, generating 40 MWh within the system, showcases Phoenix Contact’s commitment to sustainability and reliability and aligns seamlessly with South Africa’s energy challenges, promising a solution that could reshape the country’s energy landscape.

It is expected that if Phoenix Contact South Africa have regular sunny days the entire building will run completely off of the photovoltaic system.

Reliable energy sources and management

Conquering challenges with a renewable solution

The aim of the project was to make use of the significant roof space to install a solar photovoltaic system plus battery back-up to be able to act during the event of load shedding. Although the solar PV systems shut down during load shedding, the storage system keeps needed systems running.

Maximizing project benefits: Leveraging advantages for organizational success

Reducing the environmental impact: By using energy storage systems that are charged by voltaic systems the company reduces their reliance on diesel generators. Diesel generators are not only expensive to run, but also harmful to the environment due to air pollution and greenhouse gas emissions. Using renewable energy such as solar power helps to reduce the environmental impact.

Cost savings: Diesel generators are expensive to run, especially during loadshedding when the power goes out. Energy storage systems charged by solar power offer a more cost-effective alternative. In the long term, the company reduces their energy costs and act more sustainably at the same time.

Security of supply: During loadshedding, a reliable power supply means the difference between production downtime and continuous production. Energy storage enables the company to maintain their critical processes and minimize the impact of power outages.

Sustainability goals: By switching to renewable energy and take environmentally friendly measures helps to fulfill their sustainability goals. This will have a positive impact on customers, investors and society.

Overall, preventative measures such as the use of energy storage and solar energy help to strengthen the resilience of Phoenix Contact South Africa, reduce costs and protect the environment at the same time.

By implementing this innovative system, Phoenix Contact South Africa is creating an easily replicable solution that can also benefit other companies facing load shedding challenges.

Hardware and implementation

Hardware used for implementation

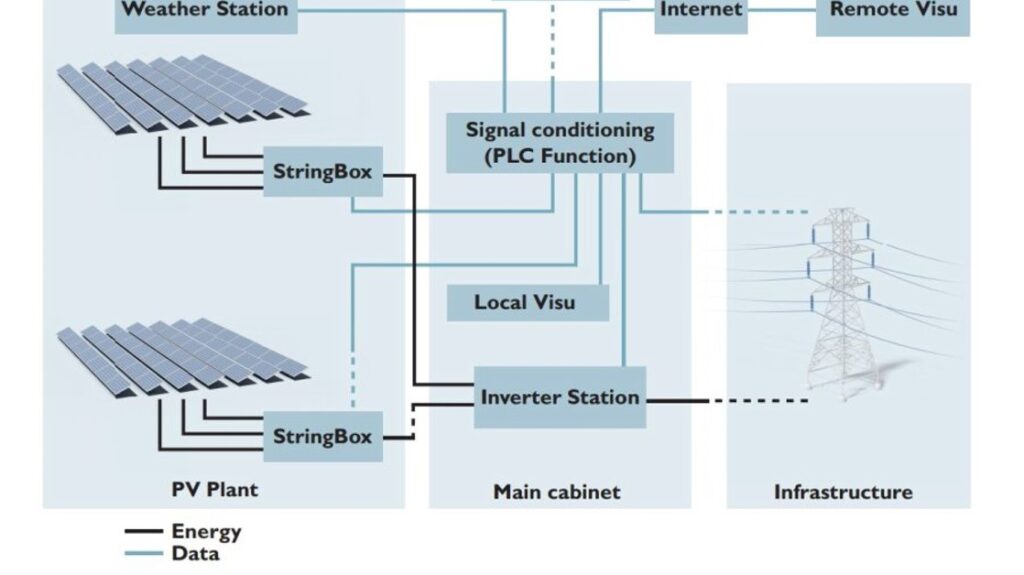

Phoenix Contact South Africa has deployed a range of cutting-edge products in the solar energy project, emphasizing efficiency and reliability. The AXC F 2152 Master Controller, along with potential future switchover to an ECP 1522 model, offers advanced control capabilities. The AXL F RS UNI 1H Serial Communications interface facilitates seamless communication for backup diesel generator and solar string monitoring. FL Switch 1008N Ethernet Communications ensure robust networking capabilities within the system.

Moreover, the project incorporates the EEM-MA770 Energy metering system, meticulously monitoring utility mains, inverter essentials, and non-essentials to optimize energy usage. Trio-PS-2G/1AC/24DC/5 24VDC Supplies provide reliable power distribution within the PLC control cubicle and string combiner panel. The solar project also integrates SCK-M-I-8S-20A Solar panel string monitor devices and SCK-C-MODBUS PV String monitor concentrators for precise performance monitoring and data acquisition.

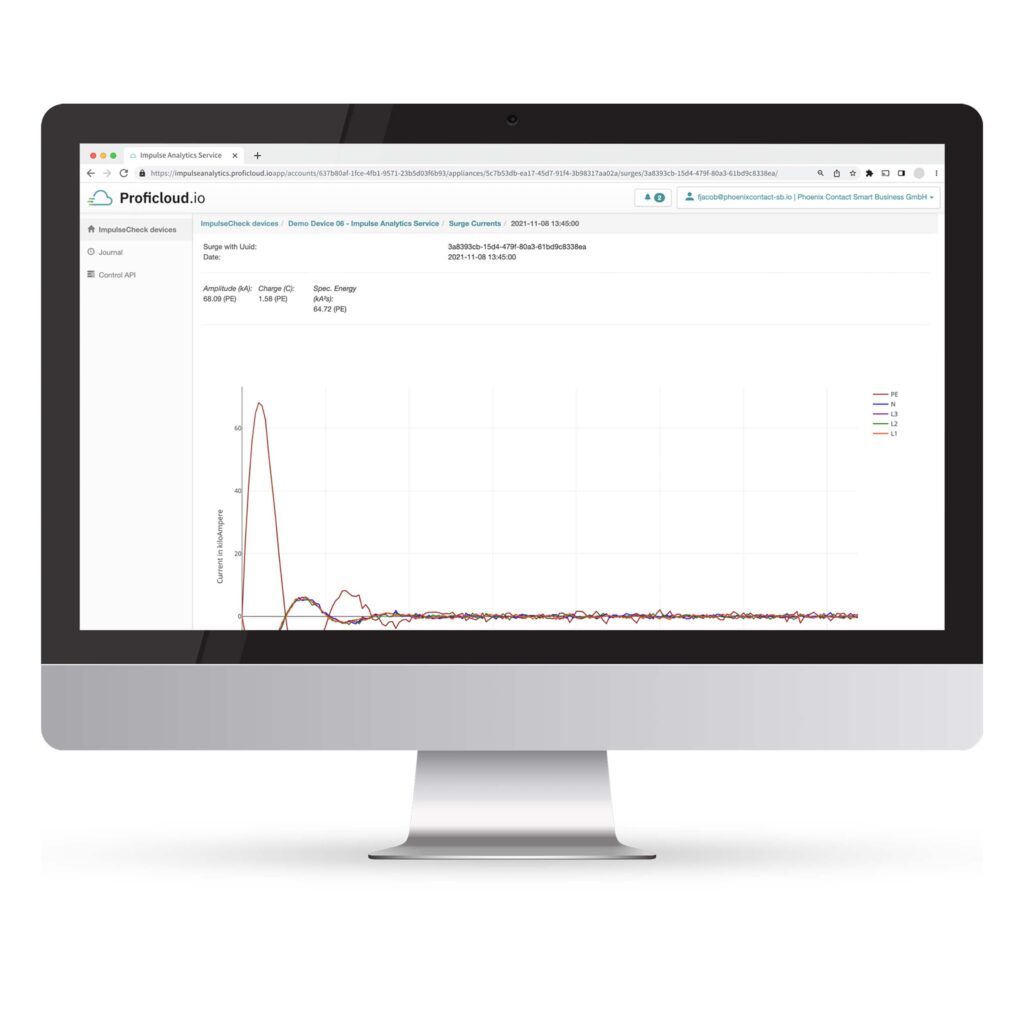

To ensure safety and reliability, surge protection devices by Phoenix Contact are deployed, providing robust protection against electrical surges for the system. Furthermore, the project utilizes dinrails and cable ducts for efficient equipment mounting and cable management within the panels. Network connectivity and data transmission throughout the system are ensured with RJ45 network plugs, along with data cables.

In conclusion, the innovative solar energy project by our colleagues from South Africa represents a significant step towards addressing South Africa’s energy challenges while exemplifying the commitment to sustainability and reliability. With its cutting-edge hardware and comprehensive integration, the project promises to reshape the country’s energy landscape, offering a model for sustainable energy generation and management.

Maximize value with Smart Services

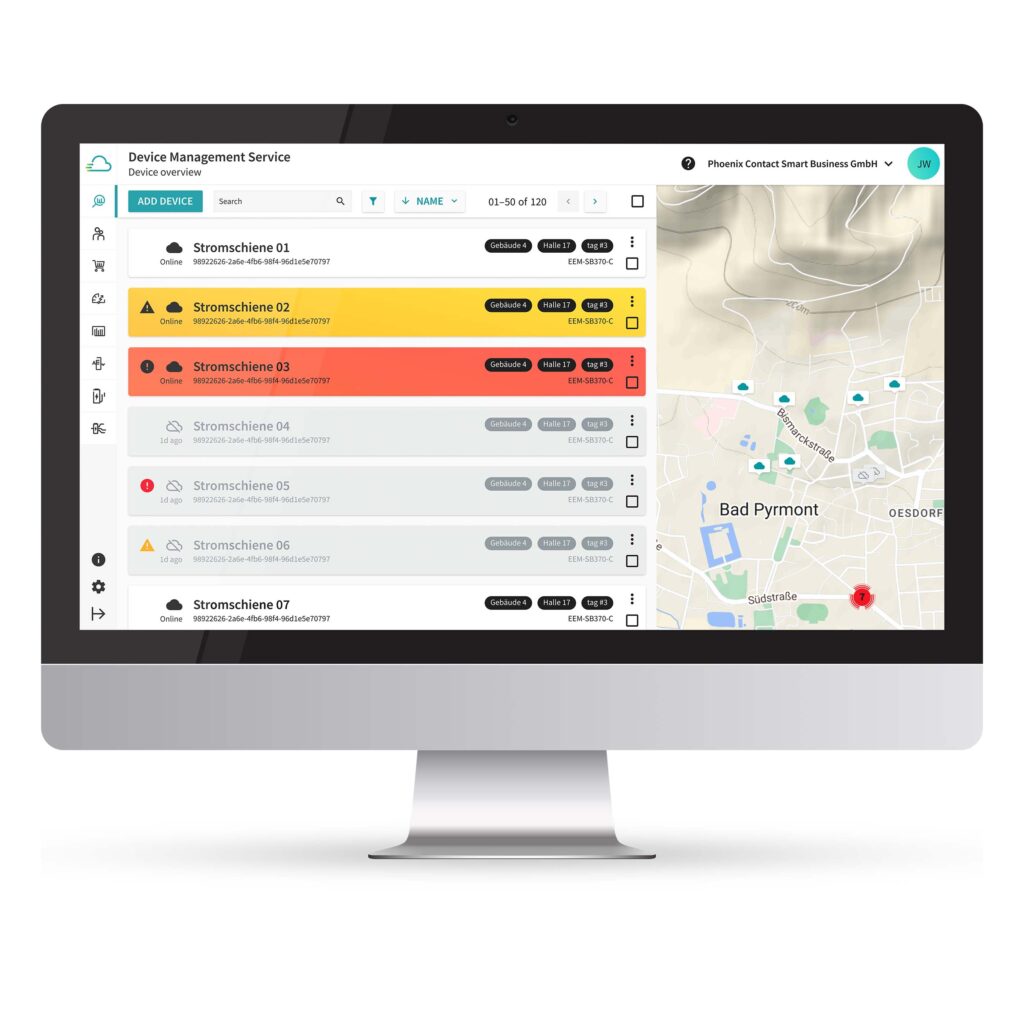

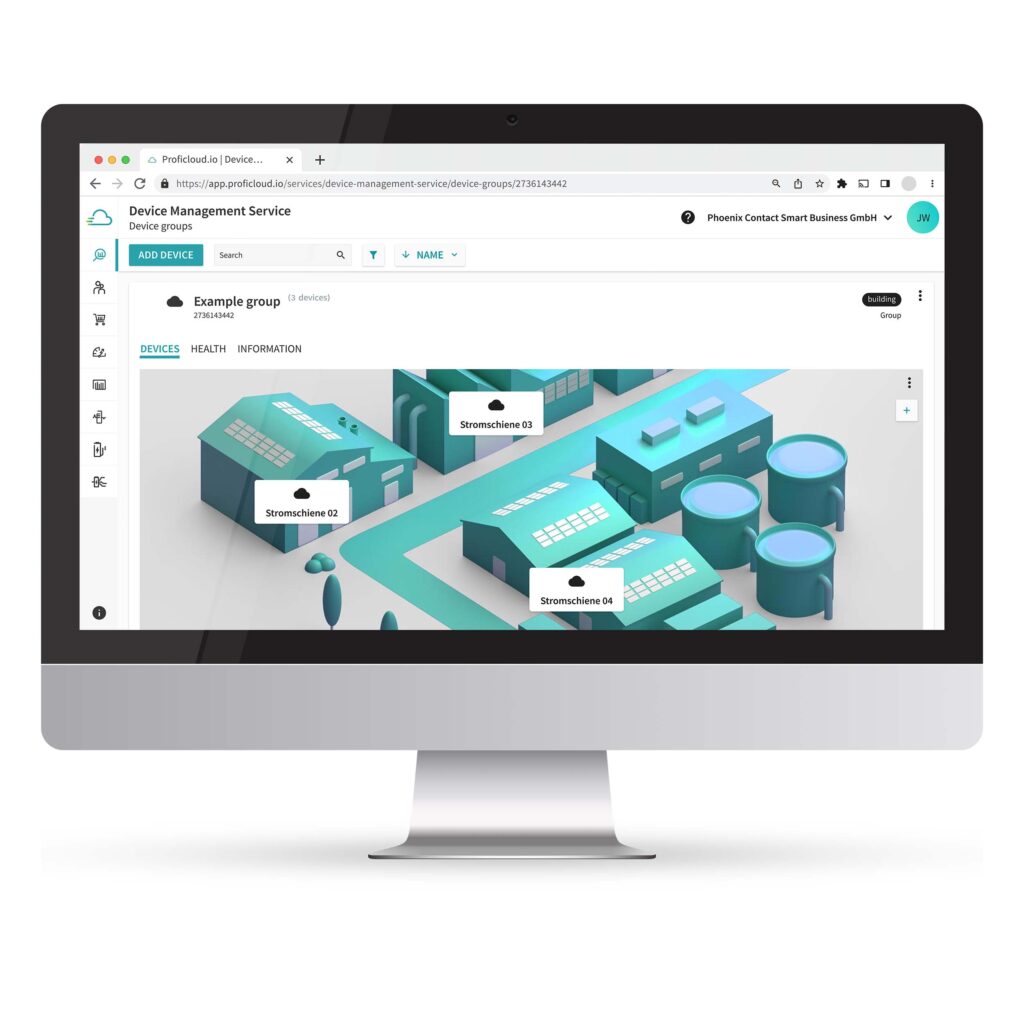

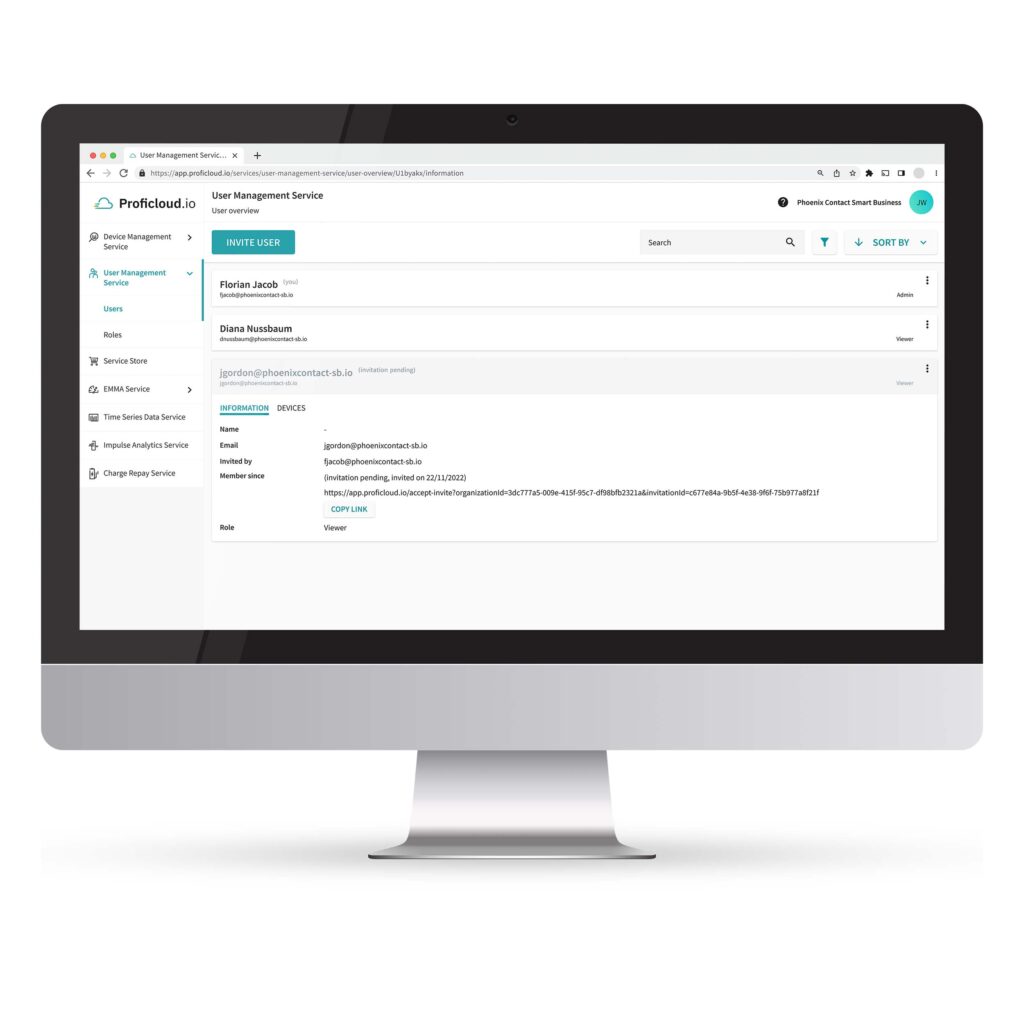

The Smart Services of Proficloud.io added the needed digitalization component of the project.

Monitoring and alerting with the Time Series Data Service

The aim by using the Time Series Data Service is to collected data to gain insights into the electricity supply and consumption within the production and administration building. The data is available for making informed decisions, e.g. how much energy is required.

The Time Series Data Service is used to continuously monitor the performance of each of the solar panel strings (8 panels) and the Smart Service will send an alert should performance decrease below a defined value.

View into the Dashboards of the project

Energy consumption and monitoring dashboard

The dashboard shows the energy consumption of the South African subsidiary of Phoenix Contact.

On the top left in the pie chart it shows which types of energy are currently being used to operate the technical devices in the company (e.g. main grid, solar or battery).

In the gauge chart with the name “Battery SOC %” (State of Charge) the charge level the battery is displayed.

Adjacent to the gauge chart, you’ll find the plain text message “Battery Charging.” This message is dynamically generated based on incoming values. The translation of the vaules into text was setup by the experts from the subsidiary and it makes possible to understand the “expert knowledge”. The actual data can be read below.

The graphs to the right show the energy generation over time. Among other things, the dashboard also shows the temperatures in the buildings directly under the roof. The roofs of the buildings have recently been insulated. To assess the effectiveness of this measure, the temperatures directly under the roof within the room and directly beneath the insulation is being monitored. This documentation will help evaluate the success of the insulation.

Solar PV system performance and load shedding impact dashboards

The dashboard shows a period of two days and how effectively the PV systems on the roofs of the subsidiary in South Africa are running. The individual lines have an offset, as some PV systems point more towards the sun in the morning, while the other PV systems point more towards the sun in the afternoon.

A sharp drop can be seen in the second curve. During this time, the subsidiary receives no electricity from the main grid. During this time of load shedding, the PV systems cannot generate any electricity, which can also be seen in the dashboards. The gauge visualizations show the “live” energy yield.

Expanding success: Building on a strong foundation

Additional features in planning

At a later stage some processes can be automated, such as internal loadshedding to prevent a larger electrical demand than supply.

The digital system can also expand into other “Building Parameters” such as water consumption, water quality, air quality or temperatures.

Further information

Hi, my name is Florian Jacob and I am glad to help you out!

Please do not hesitate to contact me. Also, if you have any suggestions or comments, just send us a message to inbox[at]phoenixcontact-sb.io and we will answer as soon as possible.