What are Smart Services? Your benefits when you use them.

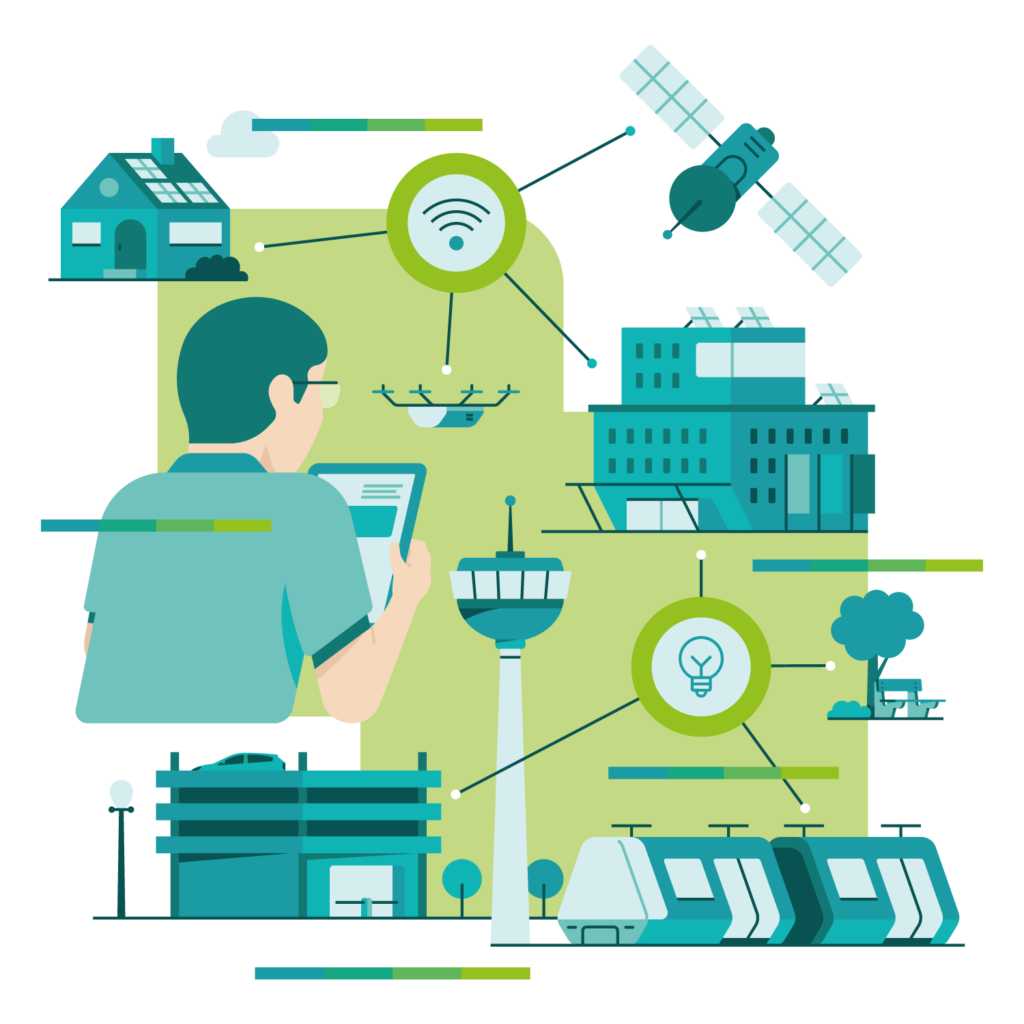

Digital Transformation streamlines processes, replacing paper and manual work with automation. Smart Services, including IoT-enabled devices and software solutions like Proficloud.io, prioritize user needs to enhance experiences.

The entire range of systems, services and software doing this is called Smart Services.

Part 1 of 2

Digital Transformation is putting an end to paper, lengthy communication chains and manual work steps. Instead, processes run digitally and almost completely automatically. New services are emerging that focus on the users’ needs and aim to create the best possible experiences. Systems such as computers, machines, or even cars can communicate with each other and exchange data due to their connection to the Internet. In the context of the Internet of Things (IoT), software solutions are needed to control and monitor this data exchange. More often than not, they are built on Cloud Platforms like Proficloud.io to make use of Cloud Computing.

The entire range of systems, services and software doing this is called Smart Services.

A short definition of Smart Services

Smart Services combine hardware such as sensor technology with software to solve a specific problem. The software is usually provided as Software as a Service (SaaS) and thus available over the Internet or – specifically – through cloud platforms. It is no longer installed locally.

Summary of characteristics

- Smart Services focus on customers and/or their specific needs. The situation and context determine when they are needed so that they can be easily integrated into ongoing processes.

- Smart Services use a huge amount of data that is regularly transferred by sensors or gathered by events.

- Usually, the services are made available via cloud, so that customers can access and analyze the data from anywhere and at any time.

Advantages of Smart Services

The need determines the technology

The technology focuses on the customer and fulfills this task perfectly. In this way, companies can offer optimal service.

It’s easily maintainable

Software can be updated via cloud (remotely) and the updates are immediately available to the customers.

You can access data from everywhere

Smart services are ideal for monitoring and controlling processes, because they can be accessed via web applications – on your computer, cell phone, or tablet.

What they can do: Examples for the industrial sector

The industrial sector uses Smart Services to optimize plant operations and leverage new sales models for customers. Smart Services complete Smart Products that were introduced by the Industry 4.0 and are a main factor in the Industrial Internet of Things (IIoT):

Smart Services for better maintenance

- Predictive maintenance:

Smart Services collect operating data from machines, such as operating time and temperature. In this way, you can better plan maintenance appointments, assess risks, and prevent errors. We have already introduced this topic in our previous blog post “How SMEs can get started with IIoT”. - Equipment as a Service:

Instead of buying a machine, a customer rents the equipment and is charged according to the consumption of energy or data (pay per use). The manufacturer is responsible for maintenance, spare parts, and repair. - Asset management:

With Smart Services, you can use machine data to optimize maintenance, repair, and machine utilization. Since you store data centrally, you can compare machines and production sites and thus optimize your workflows over time.

Smart Services for better energy management

- Determine the energy consumption per assembly group:

Smart Services enable you to visualize energy consumption per assembly group – in manufacturing times (active, production) and in standby times (passive, off-hours, weekend). You can compare the energy intake of manufacturing times with the intake of standby times. Thus, you determine the proportion of energy consumption in passive times. - Determine the energy consumption at different assembly times:

You can compare the energy consumption of an assembly group at different assembly times. This comparison includes the respective production figures. - Determine CO² emission:

You can use Smart Services to relate the number of pieces produced to the corresponding energy consumption (kWh). In this way, you know the CO² emission per piece. - Detect peak loads:

If you know peak loads, you can derive measures to optimize your energy management. Specifically, you can determine when it’s best to power on machines. Smart Services detect peak loads because they collect all necessary data and analyze it.

Coming up next week

Other use cases

The catch: challenges of Smart Services

Phoenix Contact Smart Business: Your trusted partner for Smart Services

Conclusion